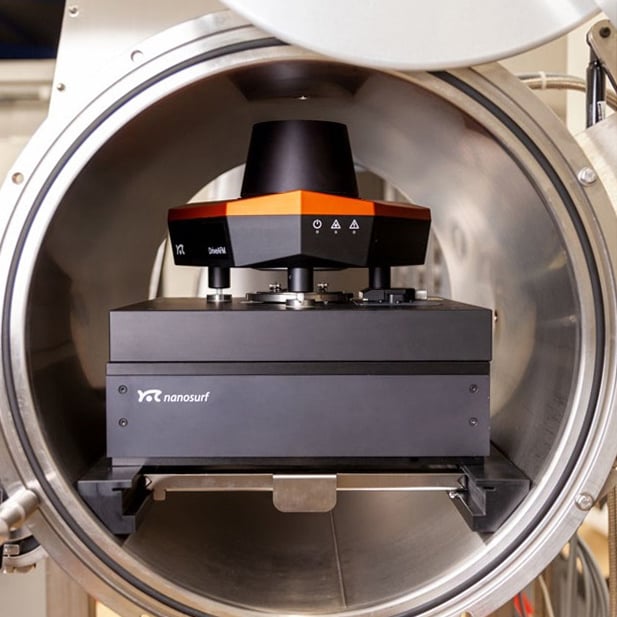

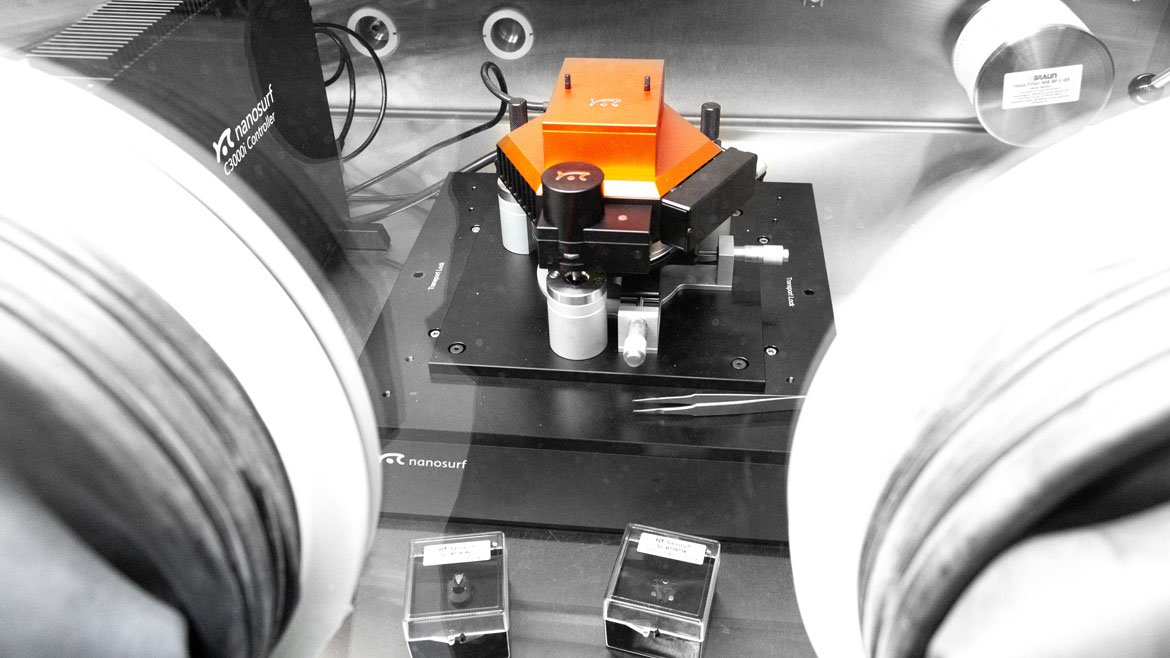

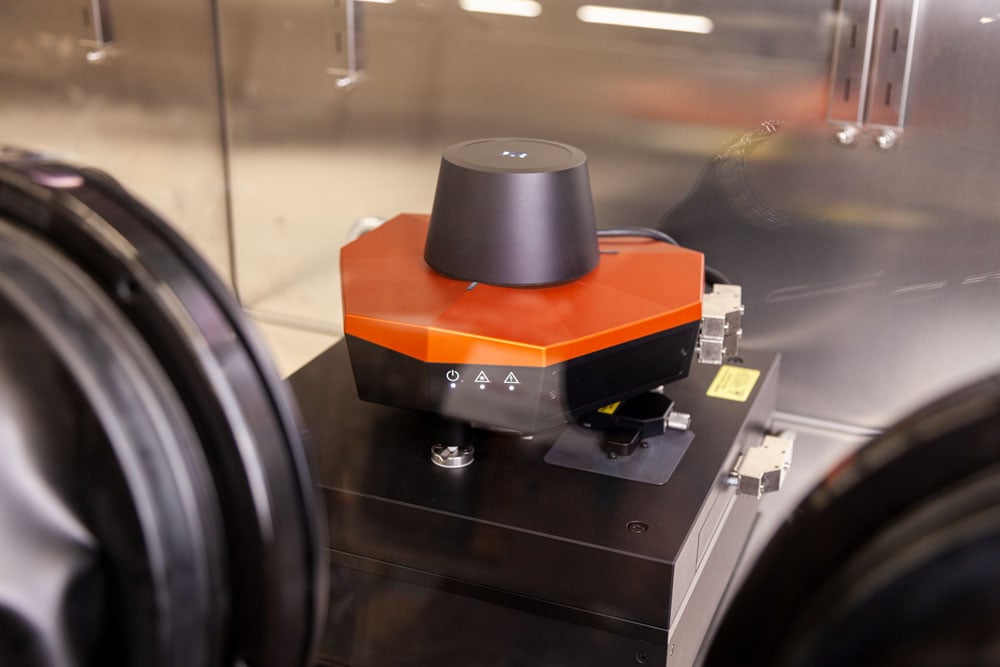

AFM Glovebox Workstation

Atomic force microscopy is uniquely suited to measure samples in-situ to monitor real-time, nanoscale surface phenomena. Research in energy storage, catalysis, 2D materials, semiconductors (ALD/MBE), organometallics, photovoltaics, and electrochemistry can often be air-sensitive and require demanding inert gas environments afforded by a glovebox. However, placing an AFM in a glovebox brings challenges such as limited sample access, cumbersome instrument operation, not to mention the additional sources of noise generated by the glovebox that can affect instrument’s performance.

Nanosurf has you covered: our turn-key glovebox AFM solutions offer a low-noise, high-fidelity nanoscale platform coupled with the most stringently controlled environment provided by the glovebox, while also addressing access and ease of use.

Nanosurf has integrated two different AFMs into high-performance gloveboxes. With these turn-key glovebox solutions available, you don’t have to worry about cutting corners on your AFM measurements to keep your high-purity environment for your experiments.

AFM Glovebox Workstation Package

- <0.1 ppm O2 and H2O environments for sample preparation and measurements

- Integrated signal feedthrough to enable AFM modes

- Reinforced table & frame to support the AFM and vibration isolation mass

- Vibration dampening to ensure optimal AFM performance

- Large load locks and touch controls to maintain environmental conditions

- Regeneratable oxygen catalyst

- Magnetic cantilever holders which are easy to remove and kinematically align upon replacement

- Fully motorized AFM approach and engage

- Motorized sample stages

- Clear, crisp top-down optics for sample alignment (capable of <2 µm lateral resolution)

What makes a good AFM for glovebox measurements?

The design and configuration of the AFM is tremendously important to be successful when operating in a glovebox. There is limited space within the glovebox, so a small footprint is desirable. Working with the gloves can be cumbersome, especially manipulating small objects like AFM cantilevers or needing to make multiple, manual adjustments to the AFM to initiate a measurement. Therefore, minimal manual manipulation is ideal to perform AFM for routine measurements. Samples can come in a variety of sizes or substrates, so an AFM capable of accommodating a wide variety of samples without additional preparation simplifies operation of the system.

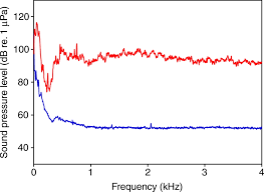

Example of a noise spectrum

Red line: AFM's noise without glovebox modification.

Blue line: AFM's noise with modification from Nanosurf's turn-key solution

What makes a good glovebox solution for performing AFM measurements?

An ideal AFM environment is diametrically opposite to that found within a glovebox. Gloveboxes maintain an inert gas environment for work with contamination-sensitive or air-sensitive materials. By design, they precisely control the atmosphere and prioritize design features such as temperature stability, O2 permeability, water content, airlock integrity, and pump performance. The glovebox with all the pumps for atmospheric conditioning introduce vibration, acoustics, and airflow which adversely affect the performance of the AFM. In contrast, an ideal AFM environment is free of excess vibration, has limited airflow, is temperature stable and acoustically quiet over a period of hours. Therefore, careful consideration about instrument compatibility and requirements are needed and not all AFMs are created equal for glovebox work.

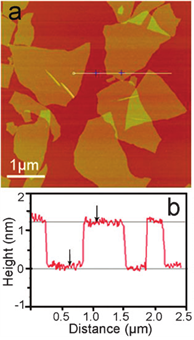

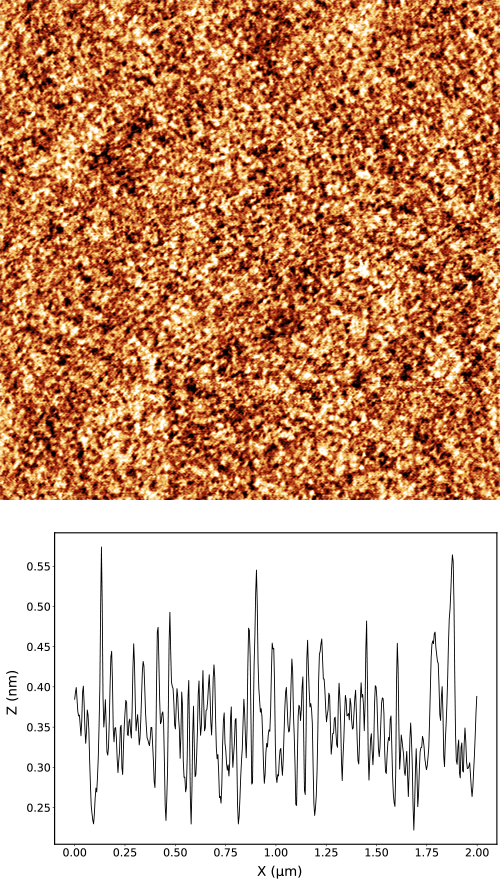

Si wafer roughness: Rq = 80 pm

Polished silicon wafer

A polished silicon wafer has typically very small roughness. In our case the roughness of 80 pm was measured with the noise floor of 20 pm. The image of the wafer shows easily recognizable granular structure and an excellent resolution of details. The cross-section of the image demonstrates that the data is dominated by the physical roughness of the sample and the vibration noise is not noticeable.

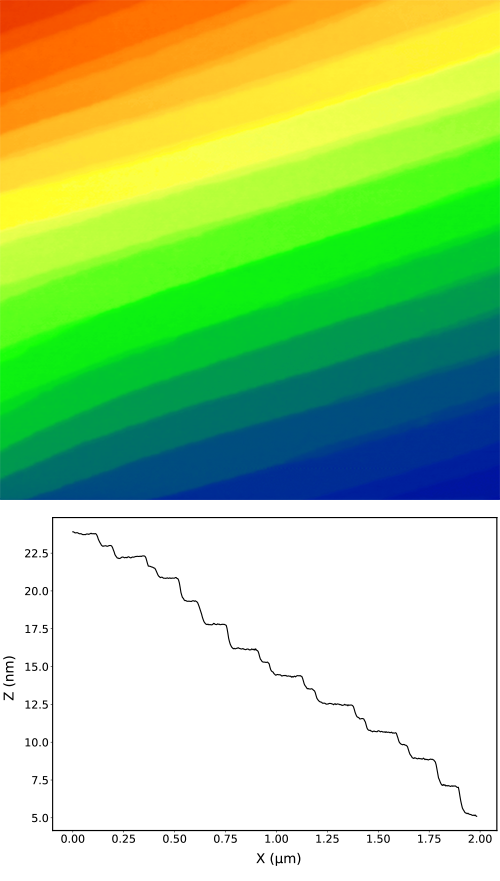

Silicon carbide crystal

A polished crystal of silicon carbide (SiC) shows clear atomic terraces with spacing of 1.5 nm and the intermediate terraces with spacing of 0.75 nm. This excellent height resolution is what is typically required for the study of graphene and other 2D materials. Both samples were measured with a DriveAFM in a Jacomex glovebox.

SiC sample: 1.5 nm spacing between main terraces and 0.75 nm between intermediate terraces

Nanosurf's Glovebox AFMs...

- ...use a tip-scanner design to ensure the samples are easy to access to load/retrieve regardless of size/shape of substrate (up to 100 mm diameter)

- ...have a compact footprint that saves glovebox real estate.

- ...use a motorized sample engagement and stage translation to allow for the operator to run the AFM without excess ‘hand-in-glove’ time. Once the sample is on the AFM, the entire system is controlled via software from outside the glovebox.

- ...have easy-to-access cantilever holders with alignment grooves facilitates cantilever exchange (FlexAFM) by always positioning the laser in the same place from cantilever to cantilever of the same dimension.

- ...have motorized laser/photodetector alignment (DriveAFM) allows for hands-free setup of the system for different cantilever shapes/sizes needed for advanced AFM characterization.

- The inherent compact design saves floorspace without compromising on performance and gives more room in the glovebox for sample preparation and other experiments.

- Samples stages and approach/engagement are motorized, meaning once the sample is loaded on the stage, all control of the AFM happens via software. Nanosurf AFMs are tip scanners which allow for a flexibility for the size/shape of the samples to be measured.

- Alignment grooves in the cantilever holder save you the effort of adjusting the laser between cantilevers.

- The DriveAFM has additional features that make it easier to use, and provides higher performance in a glovebox.

- DriveAFM has a fully motorized optical path allowing alignment of the laser and detector can be controlled via the software.

- There are no small, cumbersome, delicate knobs to turn to load a sample or align the AFM for operation.

What are the applications for a Glovebox AFM?

Any application which requires environmental control, especially of O2 and H2O contamination, will require putting the AFM in a glovebox. Such applications include 2D materials research, semiconductor nanoscale analysis, Lithium (or other Alkali metal) research for energy storage, ALD/MBE materials research, free radical surface work, molecular machines and more.

Nanosurf has a turn-key solution for 2D materials processing in a glovebox. The FlexAFM is the first AFM specially configured to characterize single-layer 2D material steps within a glovebox. The FlexAFM is guaranteed to be able to resolve step heights ≥200pm within a glovebox at an affordable price. This configuration is ideal for researchers who do not want to expose their materials to the atmosphere for characterization during exfoliation and sample processing, but still need to know dimensions, thickness and basic topography.

For those applications where a more detailed analysis is necessary, such as measuring the magic angle of bilayer 2D materials via nanoelectrical characterization, the turn-key high-resoltution solution is the DriveAFM in a glovebox. The standard DriveAFM offers performance without compromise, bringing together world-class AFM performance with the flexibility of a large scanner and faster acquisition speeds.

Interested in Glovebox Solutions?

Get to know Nanosurf's Glovebox Solutions! Reach out to us to discuss your application with one of our seasoned AFM experts, to get a budgetary quote or schedule a product demonstration or exploratory meeting.