Industrial AFM Solutions

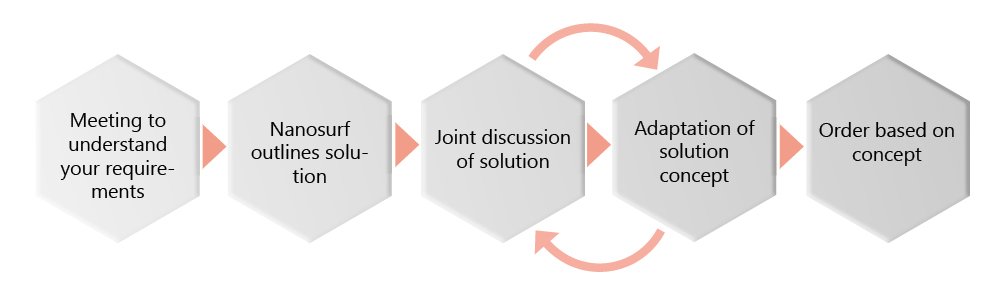

For sub-nm Surface characterization of highly polished concave and convex glass, large optics, for production-scale QC, and R&D, Nanosurf offers the unique service of engineering bespoke AFM systems configured specifically to your unique application and performance requirements. Thanks to years of experience designing solutions for complex measurement situations, we have a large selection of component solutions to apply to your system. Our engineering and development team will work with your team to understand your needs and iteratively design an AFM system for your individual application.

Speak with an ExpertHigh-performance AFM

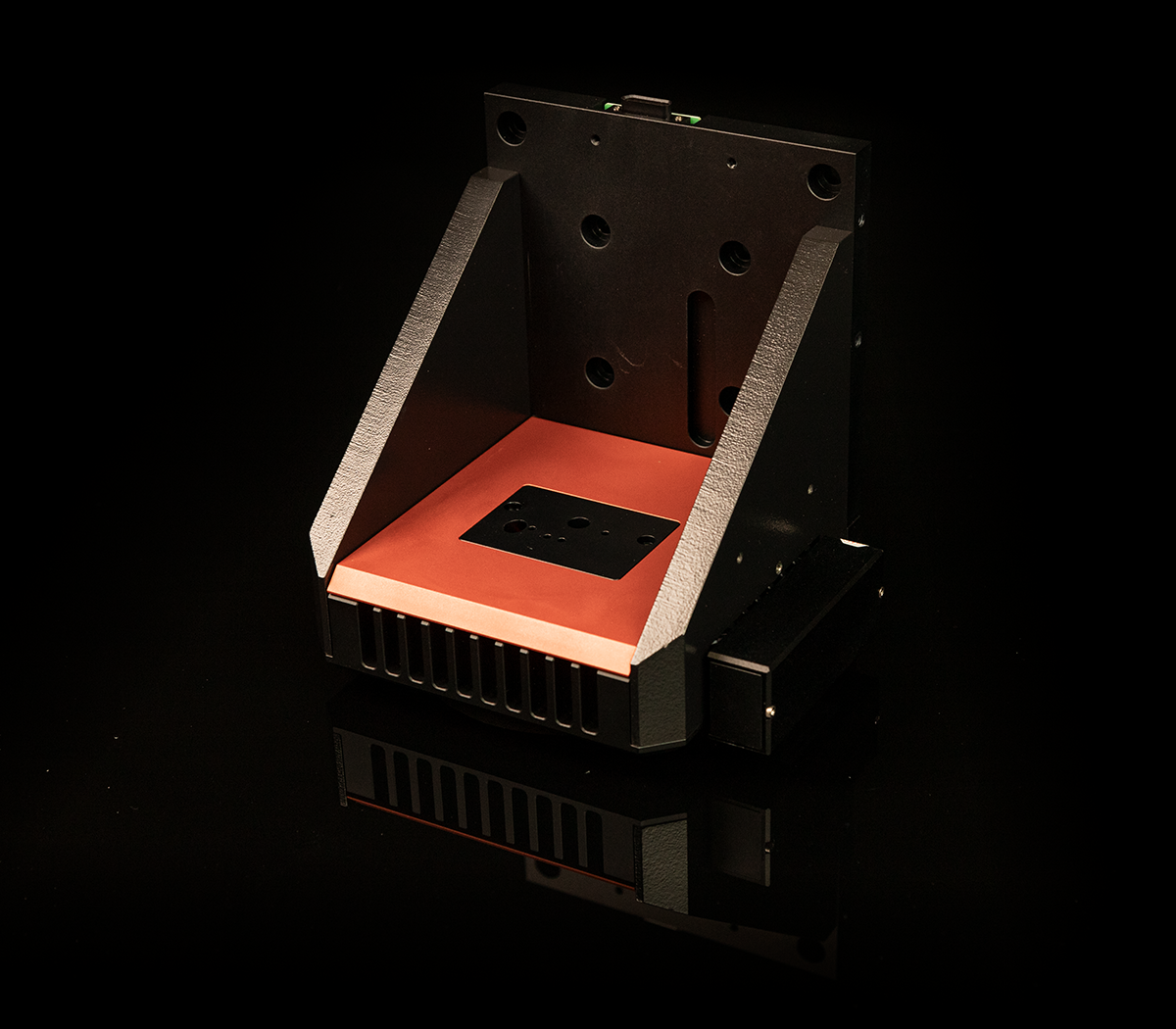

Nanosurf's tip scanner technology allows our scan heads to be easily mounted, preserving the scanner performance when investigating heavy samples.

5 Degrees of Freedom

We design the sample stage, scan head mount, and geometry of the AFM system based on your sample and measurement requirements, regardless of size, weight, and curvature. With up to 5 axes of freedom, our sample stages allow measuring any position on your sample.

- Virtually no restrictions to sample weight, size, and geometry

- High repositioning accuracy

- Highly reproducible results

System Optimization

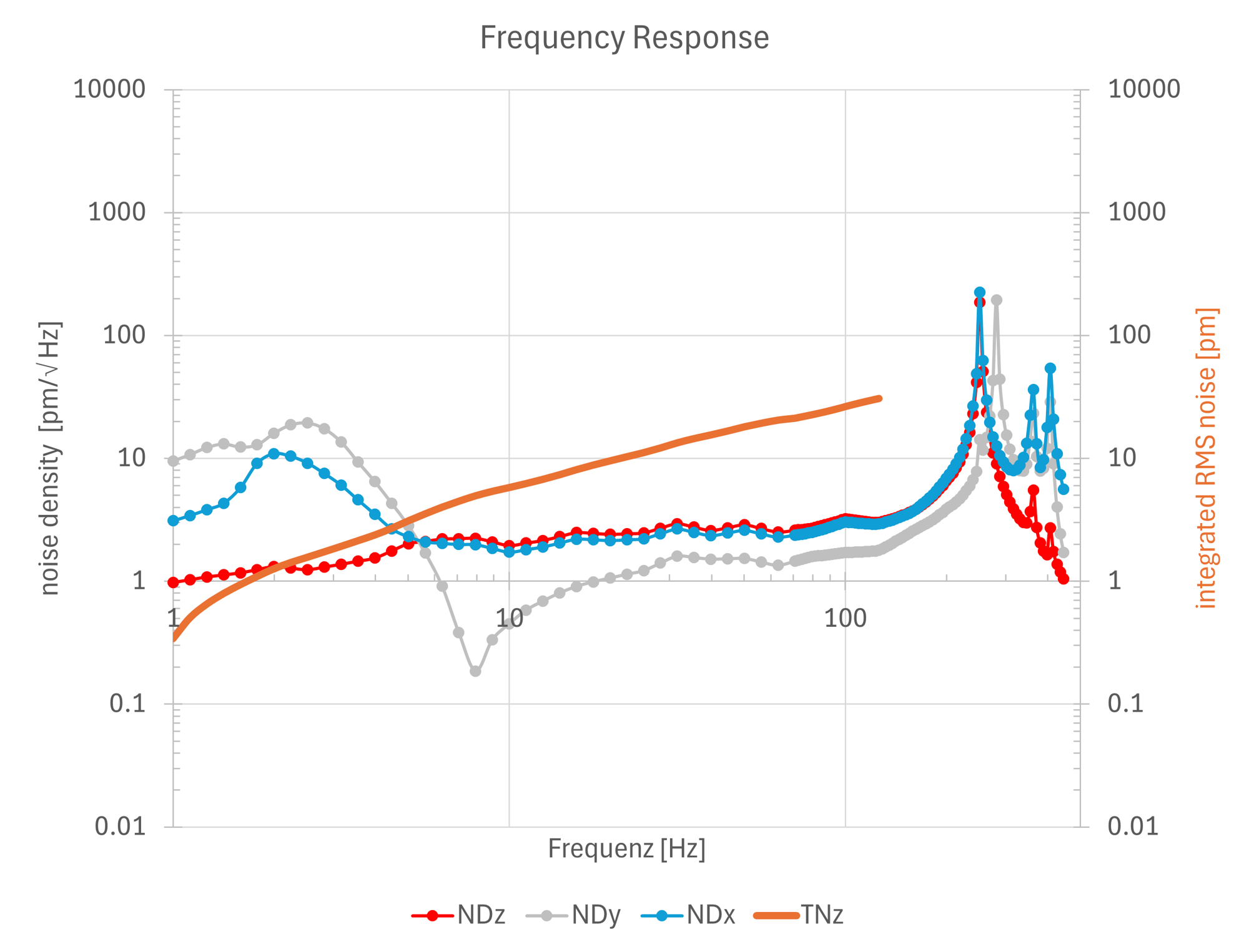

Usually AFM is highly sensitive to environmental perturbances like acoustic noise, temperature variations and floor vibrations. By building detailed models of your system and running performance simulations that include environmental factors, we are able to ensure all your requirements are met by the final system upon delivery.

Automation

For factory-scale process integration, we offer automation solutions that go beyond simple measurement series. Talk to our automation experts to see what is possible with MES.

Cleanroom Compliance

Where precision is paramount, so is cleanliness. For applications like those found in areas such as the semiconductor industry, we design our systems to fulfill the most stringent cleanliness requirements: all materials and components are cleanroom certified, and assembly is carried out in a clean environment.

Safety and Reliability

All of our systems can be equipped with a programmable logic controller (PLC) that ensures safe operation for your employees and your samples. If one of the system security conditions is triggered, e.g. safe limited speed (SLS) is exceeded, the emergency-stop button is pressed or an AFM cantilever is lost, the PLC executes a safe torque off (STO).

Features

Large Selection of Operating Modes

Safe and Reliable

Closed Loop Motion Control

5 Degrees of Freedom

ISO 6 Cleanroom Compliant

Tiltable Scan Head

Automation

Air-Bearing-Based Sample Translation

Fully Customizable

Operating Modes

Standard imaging modes

- Static Force Mode

- Lateral Force Mode

- Dynamic Force Mode (Tapping Mode)

- Phase Imaging Mode

Mechanical properties

- Force Spectroscopy

- Force Modulation

- Force Mapping (Stiffness and Modulus, Adhesion)

Electrical properties

- Conductive AFM (C-AFM)

- Scanning Spreading Resistance Microscopy (SSRM)

- Piezoelectric Force Microscopy (PFM)

- Electrostatic Force Microscopy (EFM)

- Kelvin Probe Force Microscopy (KPFM)

- Scanning Microwave Microscopy (SMM)

- Magnetic Force Microscopy (MFM)

Software

Nanosurf's industrial AFM systems are run by our standard C3000/CX control software, which is well known for its ease of use and flexibility. Through the scripting interface even complex automation tasks can be realized by skilled end-users or our software engineering team - from small measurement automation series to full-scale MES integration.

Download the Industrial Solutions Brochure

The PDF brochure includes details on the process of engineering an industrial system, and examples of successful implementations.

Example Implementations

Motorized XYZ translation stage for extra large samples

Motorized XYZ translation stage for extra large samples

Designed for very large samples, this high-load, high-precision custom stage solution is an example of cutting edge engineering. With more than 2 meters in length and 1.45 meters width, and weighing more than 2 tons, it is one of the largest stages ever built. The system, that uses air-bearings, a drive belt, and stepper motor for sample positioning, was designed for use with the NaniteAFM.

| Description | Specification |

| Max. traverse path XYZ | 550 mm; 1555mm; 50 mm |

| Resolution XYZ | σ = 1 µm |

| Repositioning accuracy | ± 5 µm |

| Absolute accuracy | ± 50 µm |

| Max. velocity | 30 mm/s |

| Sample platform size | 785 × 1950 mm |

| Sample size | max. 540 × 1500 × 210 mm |

| Sample weight | max. 500 kg |

| Stage size | 1450 × 2200 × 1350 mm3 |

| Stage weight | 2250 kg |

| Stage technology | Air-bearings, drive-belt, stepper motor |

| Noise level | < 0.75 Å (NaniteAFM 110-µm scan head in quiet environment) |

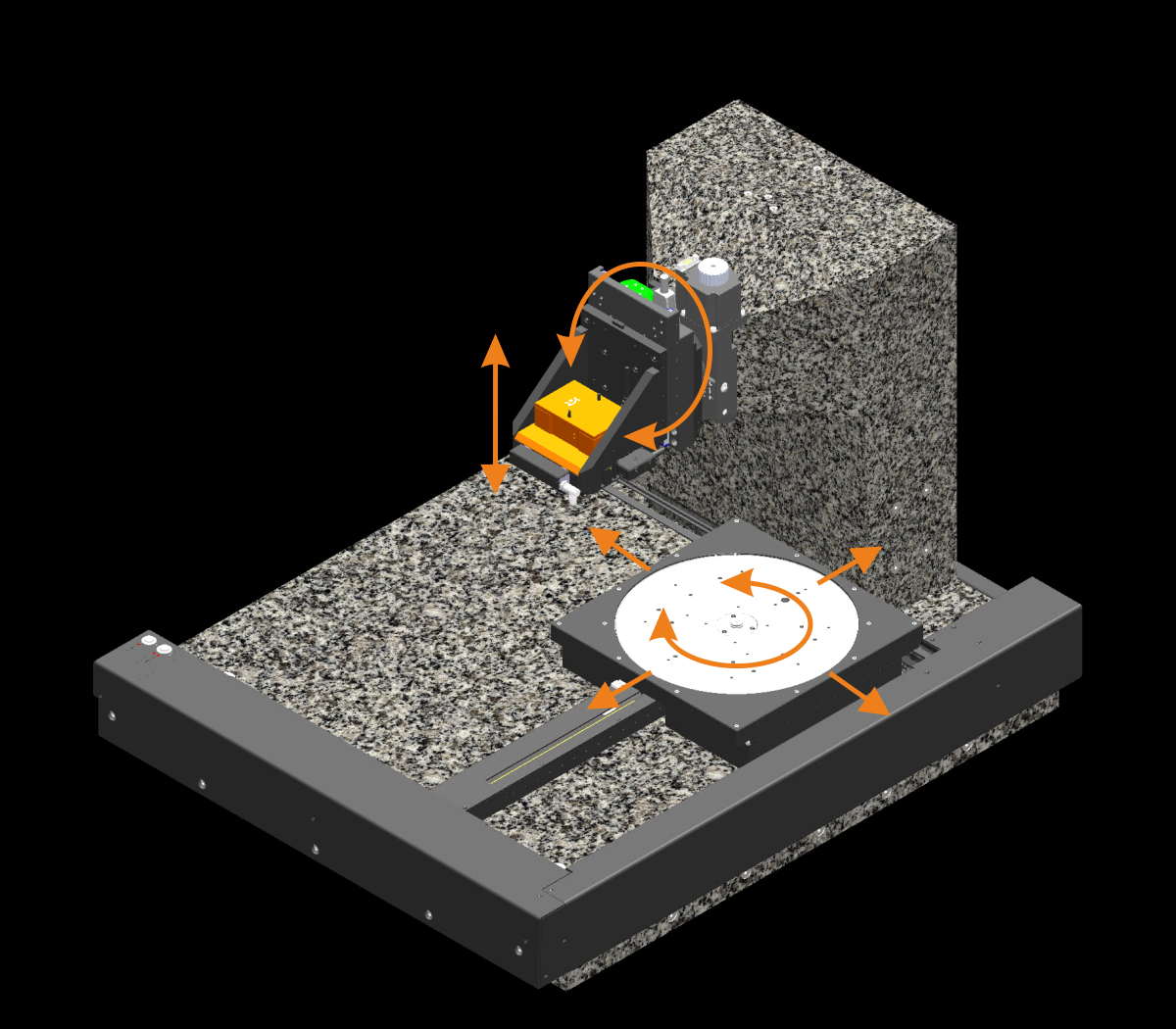

Motorized XYZΦ translation stage

Motorized XYZΦ translation stage

Analyzing each section of a large, heavy sample from different perspectives, all while maintaining a sleek design, poses a major challenge. This platform allows for the sample to move and rotate to meet this goal, while also keeping noise levels impressively low.

| Description | Specification |

| Max. traverse path XYZΦ | 230 mm, 485 mm, 20 mm, 360° |

| Resolution XYZ/Φ | 0.1 µm / 0.0001° |

| Repositioning accuracy XYZ/Φ | ± 1 µm / 0.001° |

| Absolute accuracy | ± 15 µm |

| Max. velocity XY/Z/Φ | 30 mm/s / 3 mm/s / 7°/s |

| Sample platform size | ∅500 mm |

| Sample size | ∅500 mm x 80 mm |

| Sample weight | max. 20 kg |

| Stage size | 1350× 950 × 1360 mm3 |

| Stage weight | 2250 kg |

| Stage technology |

Linear motors / spindle-stepper motor / harmonic drive / air bearings |

| Noise level | < 0.40 Å (Flex-Mount scan head in quiet environment) |

Measurement Examples

#{ row.name }

There are no items to display.

#{ item.resourceType }

#{ item.date_text_field }

#{ item.name }

#{ truncateText(item.metadescription) }

#{ item.readmoretext }No posts available

Interested in Industrial AFM Solutions?

Discover the possibilites of custom engineered industrial scale AFM systems! Reach out to us to discuss your application with one of our seasoned AFM experts. Schedule an exploratory meeting to start the process.