Nanite

Integrate Nanoscale Measurements

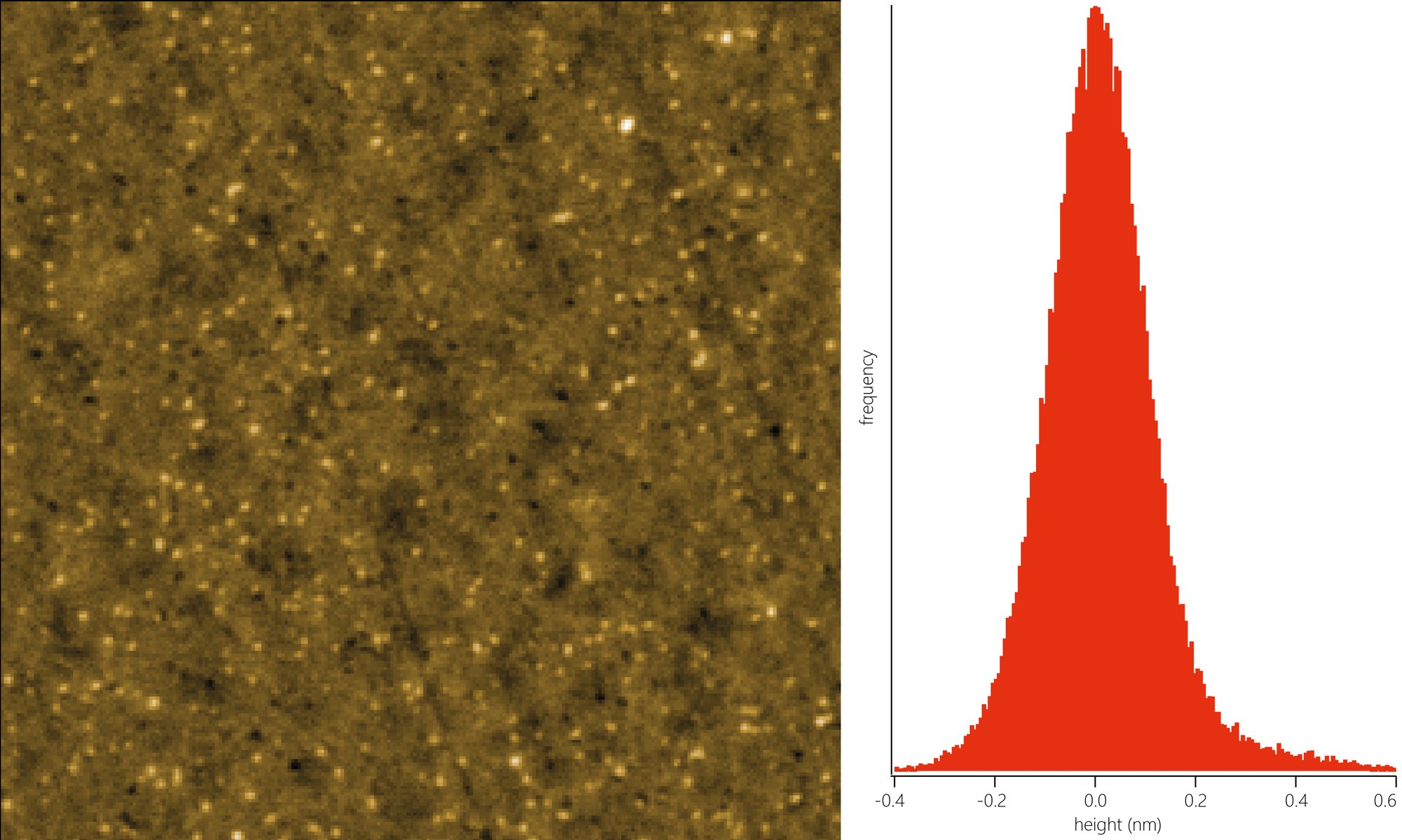

Surface morphology is an important property for many high-tech surfaces with features as small as a few nanometers and surface roughness below one nanometer. The Nanite is the tool of choice for surface analysis of workpieces of all shapes and sizes. It delivers nanoscale precision measurements and is itself small enough to allow integration into virtually any imaginable environment.

Speak with an expert

Quantitative Surface Analysis at the Nanoscale

Accurate surface analysis at the nanoscale is essential across various industries, spanning from nanotechnology to data storage and precision optics. The Nanite serves as an invaluable instrument for unveiling intricate nanoscale surface details, including sub-nanometer roughness crucial for diverse applications.

Sample Limitations - None

Near Limitless Integration

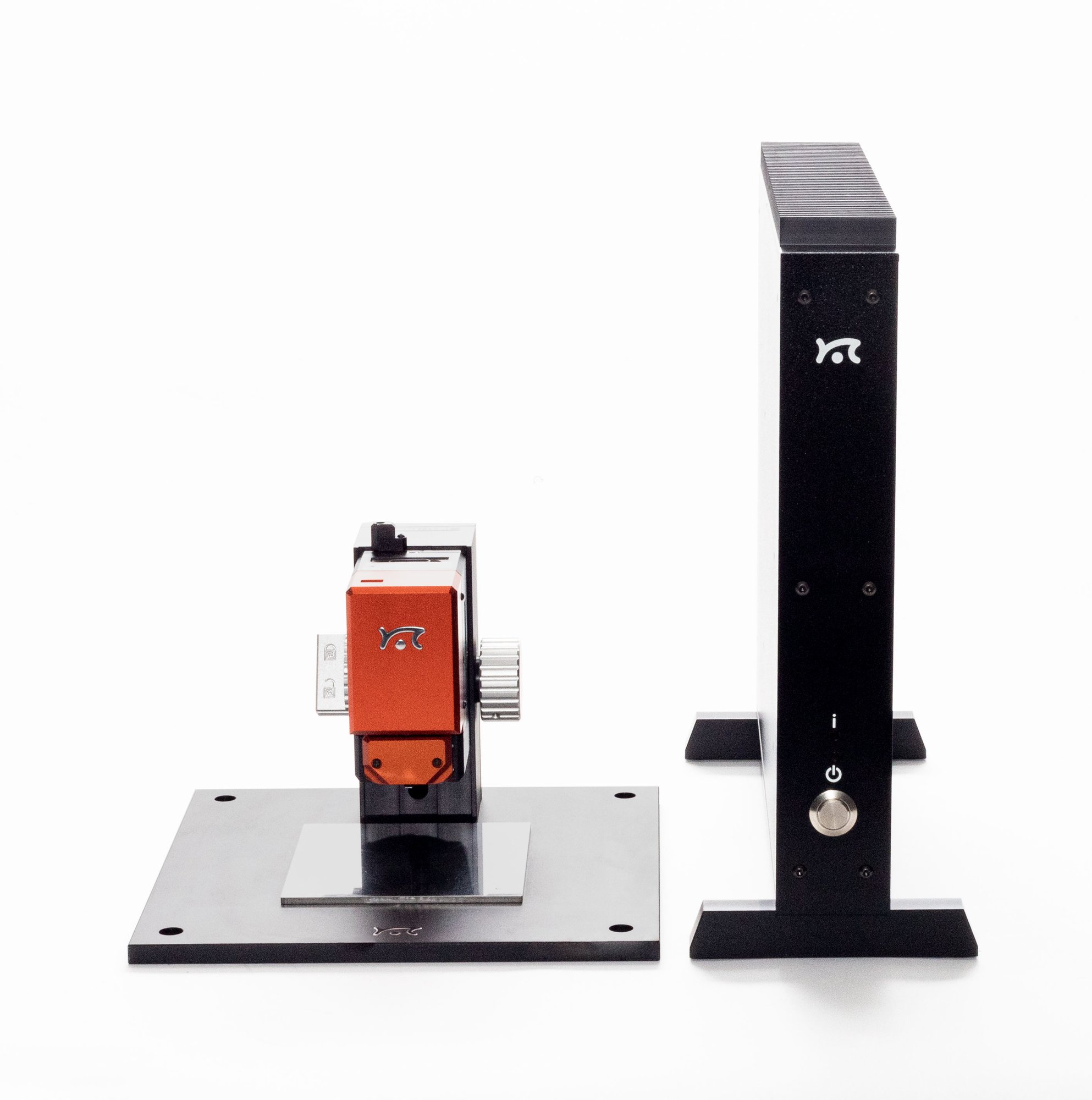

The compact NaniteAFM (less than 48 x 87 x 61 mm) integrates seamlessly into existing user systems or custom stages designed by Nanosurf's engineers. This flexibility allows researchers to incorporate AFM capabilities into their established workflows, often without significant modifications. Furthermore, the instrument's scripting interface empowers users to integrate AFM control into their existing setups or leverage Nanosurf's expertise for stage design and automation features.

Nanite Features

Designed for Integration

Integrated Top and Side View Camera

Stand-Alone Solutions

No Inherent Sample Size Limit

Bespoke Solutions

Suited for Concave Survaces

Nanite imaging modes

Standard imaging modes

- Static Force Mode

- Dynamic Force Mode (Tapping Mode)

- Phase Imaging Mode

Electrical properties

- Conductive AFM (C-AFM)

- Electrostatic Force Microscopy (EFM)

- Magnetic Force Microscopy (MFM)

Mechanical properties

- Force Modulation

- Force Spectroscopy

- Force Mapping

Lithography and Nanomanipulation

C3000 Control Software

- Cantilever calibration by Sader method and frequency sweep

- Highly configurable graph area with mode-dependent auto-layout: the software automatically shows the relevant graphs and information

- Easy file handling with comfort features: auto apply naming conventions, Windows Explorer integration, image gallery, bulk renaming.

- Includes a powerful scripting interface: automate and extend capabilities according to your needs.

- Compatible with most programming environments (e.g. LabView, Python, MatLab, C++, Java, and more)

- Spectroscopy wizard: follow easy steps to set up spectroscopy measurements

- One software UI for all scan heads: no additional learning curve if you use multiple Nanosurf AFM systems

Download the Nanite Brochure

The PDF brochure includes details on the Nanite's technology, application examples for different areas of interest and system specifications.

Example Measurements

#{ row.name }

There are no items to display.

#{ item.resourceType }

#{ item.date_text_field }

#{ item.name }

#{ truncateText(item.metadescription) }

#{ item.readmoretext }No posts available

Interested in Nanite?

Get to know the Nanite! Reach out to us to discuss your application with one of our AFM experts, discuss your needs for a budgetary quote or schedule a product demonstration or exploratory meeting.