Superlubricity and Stress-Shielding of Graphene Enables Ultra Scratch-Resistant Glasses

Glass surfaces are ubiquitously present in today’s world and the requirement for damage-resistant surfaces will grow in the future with innovations such as wearable electronics emerging. For such applications, the mechanical properties and stability of the glass are paramount. Defects, such as cracks or scratches, which are either inherently present in the material or acquired during usage, play a curial role in the stability of these materials.

This paper reveals that the coating of glass surfaces with only a few layers of graphene, but also using other 2D materials, can help to significantly reduce wear abrasion and hence damage of glass surfaces by introducing superlubricity of these composite materials. The DriveAFM was used in lateral force mode to show and understand the different frictional behavior of graphene-coated and non-coated silica glass.

Sahoo et al., ACS Appl. Mater. Interfaces (2023) 15, 51905-144

AFM data in this publication were obtained with FlexAFM

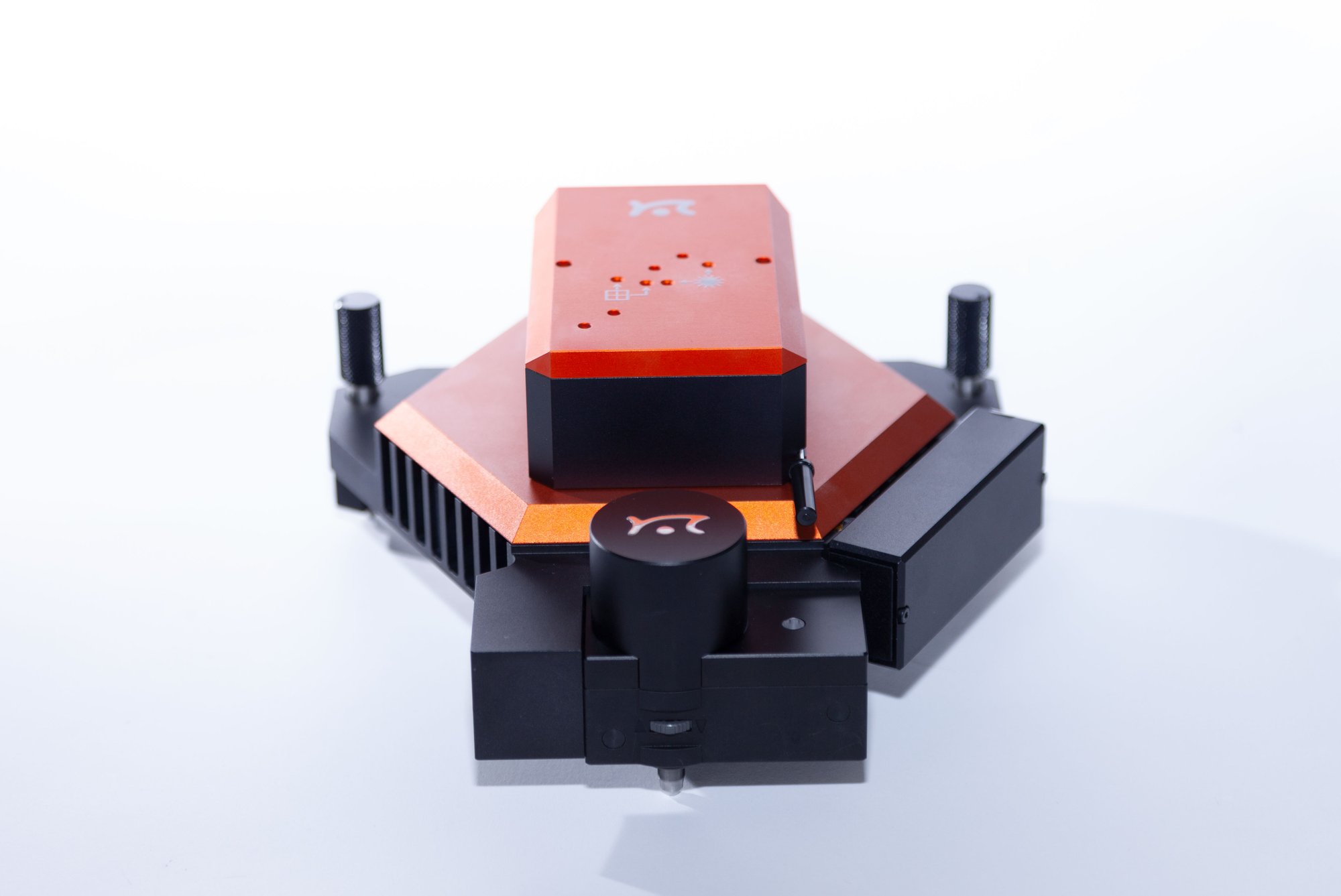

The FlexAFM has been the instrument of choice for hundreds of researchers in need of a reliable and versatile atomic force microscope system. Built with ease of use and configurability in mind, the capabilities of the FlexAFM cover most research needs: Configure your FlexAFM for 2D materials research in a glovebox, or integrate it with your inverted optical microscope for biological applications - no matter what your research goals are, the Nanosurf FlexAFM provides you with an affordable mid-range instrument that you can expand and upgrade as your requirements evolve.

Related Resources

#{ item.resourceType }

#{ item.date_text_field }

#{ item.name }

#{ truncateText(item.metadescription) }

#{ item.readmoretext }