Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

Héctor here, your AFM expert at Nanosurf calling out for people to share their Friday afternoon experiments. Today I investigate an unknown sample with microwave microscopy.

If I trained you on the use of AFM, at some point or another you heard me saying:

“do small steps, try to go from a known sample to an unknown one using a semi-unknown sample in between”.

This is something I follow myself, and is why sometimes I propose basic samples for fridayAFM, (and try revisiting them with new experiments as often as possible).

Ink is one of those samples. Ink has been part of a couple of fridayAFM experiments so far because it can be applied to many different surfaces, it forms nanostructures, and it doesn’t increase the roughness of the surface too much.

For instance, some time ago I imaged how ink changes the surface of paper and covers it with tiny micro-spheres.

Then I used it on egg membrane to see if I could detect spheres deposited on top of the membrane fibers (before trying to deposit yeast on the same membrane).

So, today ink will help me on learning a bit more about scanning microwave microscopy (SMM for short).

At home I found this set of metallic color pens. Apparently, from the descriptions I could find, the metallic finish is given by metallic flakes added to the ink. These flakes are in suspension with the ink, and once the ink dries they remain on top of the painted surface reflecting light in such a way that resembles a metallic surface.

In other words, this ink should provide me with a surface with particles with low and high impedance, a nice test sample for SMM. So I started by painting a glass slide with the markers. By the way, glass is a surface that we know pretty well also. We tried cleaning glass in the past.

and also tried coating it to change its wettability.

In other words, we know how the glass looks like, how the ink looks like, and the only unknown should be the metallic flakes (if there are any). Can we see the metallic flakes? Not on the topography, at least to me they don't seem evident.

Can the SMM help us?

The SMM system operates by sending a radiofrequency signal through the probe down to the sample surface. The ratio between the generated signal and the reflected signal is proportional to the conductivity of the surface.

How the reflected signal is generated? When transmitting microwaves, each interface is a source of impedance mismatch, which means that each interface splits the incident wave onto a transmitted and a reflected wave. This is true for all the elements in the circuit, including the probe-surface interface. So, as the probe moves the coupling changes and the amount of reflected signal changes in response to changes in the surface.

Now, why the resonator in the circuit, and why the title of this post? As I said, each interface adds new waves to the circuit, the purpose of the resonator is to select some of those frequencies and null the others (or more precisely, let them decay). But the resonance of the circuit is dictated not only by the resonator but also by all the interfaces... which means, that in order to have the maximum sensitivity... we have to tune the frequency of the generated signal to match the resonance of the whole thing, and today for this experiment... it was 4866 Hz.

So, how the ink looks like in terms of microwave absorption?

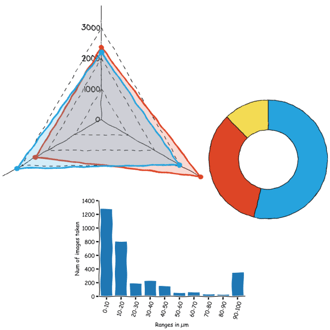

Microwave absorption lets us see the metallic flakes easily. They shine in bright colors in the absorption maps. We can see that they tend to have about 10-20 μm in size and that they are quite dispersed (at least in the green ink, on the grey they seem buried).

What is more interesting, is that in some cases the drying process seems to have drifted the flakes towards the edge of the drying ink, while in others the distribution is quite homogeneous (think about this when doing small scan ranges and not finding anything).

One open question: there seem to be many particles with low conductivity (i.e. dark), are they made of different material or the same material but just different structure? Like for instance, hollow capsules, or filled with solvents... For now I have no answer.

Let's recap. Metallic ink seems an interesting test sample for SMM. There are a few open questions, like what are the low conductivity parts, and what is the composition of the metallic flakes, but if all that maters is testing the contrast of the system (to see if is has been tuned properly), then this is a suitable sample. Additionally, we learned a little bit more about ink, which is likely to be useful in the future.

I hope you find this useful, entertaining, and try it yourselves. Please let me know if you use some of this, and as usual, if you have suggestions or requests, don't hesitate to contact me.

Further reading:

Application note: Unveiling the Power of Electrical Modes.

Application note: Scanning Microwave Microscopy for the Semiconductor Industry

28.10.2025

Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

27.10.2025

Read this blog and discover advanced alloy engineering and cutting-edge AFM techniques for high-resolution, ...

14.10.2025

Discover how WaveMode technology resolves the tobacco mosaic virus structure under physiological conditions with ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

11.07.2024

FridayAFM: learn how to perform datamining on large sets of AFM data.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.