Process intermittent quantitative analysis of the wear of ultra-small micro end mills

Micro milling with ultra-small micro end mills is characterized by high wear. The rapid wear-induced rounding of the cutting edge leads to unfavorable cutting conditions. So far, there has been a lack of both appropriate measurement technologies and knowledge about the most suitable wear parameters for micro end mills. Researchers of the RPTU in Kaiserslautern have integrated the NaniteAFM, with its small footprint, into a dedicated micro milling center, to be able to characterize milling tools without unclamping of the workpiece or tool. This paper describes the on-machine characterization of micro end mills via the AFM and deduces suitable wear parameters for micro end mills. Using the atomic force microscope, the wear progress of ultra-small micro end mills is analyzed, which leads to a better understanding of wear mechanisms in micro milling.

S. Kieren-Ehses et al.

AFM data in this publication were obtained with NaniteAFM

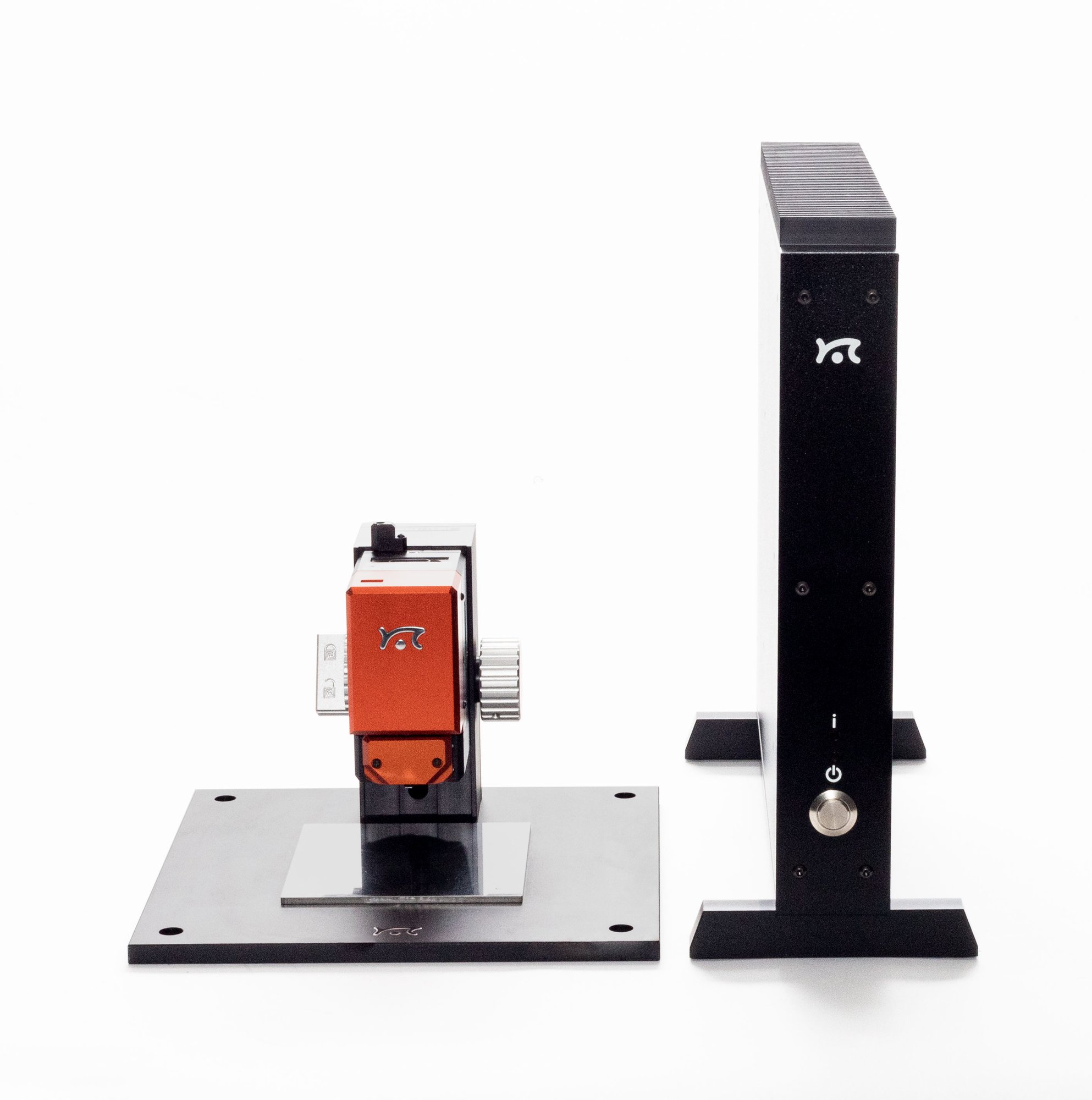

Most AFMs are limited in the type and size of samples they can handle. The NaniteAFM by Nanosurf is the market leading solution for AFM integration with least restriction to the sample dimensions. The NaniteAFM contains everything needed to operate independently, paving the way for easy integration: All you need is 300 cm3 in space and a stable docking site to mount the AFM

Related Resources

#{ item.resourceType }

#{ item.date_text_field }

#{ item.name }

#{ truncateText(item.metadescription) }

#{ item.readmoretext }