High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

Polymers are essential components in many devices and materials used in everyday life, often without us noticing. Materials such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate

(PET) are commonly found in food containers, wrapping films, and bottles. Polymers also play a key role in the organic LED screens of smartphones, while synthetic fibers like polyester and nylon are widely used in clothing. In industrial applications, polymers are valued for their surface properties, including permeability control, mechanical durability, and light reflectivity.

A bottlebrush polymer deposited on mica in liquid environment imaged with DriveAFM in WaveMode.

It is possible to resolve the backbone and the individual side chains.

The properties of bottlebrush polymers are closely linked to their molecular conformation. To fully understand these materials, researchers need a technique capable of imaging individual polymer molecules directly on the surface of interest, with the highest resolution in all three spatial dimensions. Atomic Force Microscopy (AFM) is well-suited for this purpose. However, not every instrument on the market can capture high-resolution images of bottlebrush polymers. With side chains spaced only few nm apart, every detail matters, including speed. The sample must reach equilibrium with the AFM tip and the rest of the system, but these conditions are disturbed by the instrument itself. Slow scanning speeds can lead to significant drift, distorting the image and making it difficult to resolve molecular features. Even under ideal conditions, perfect equilibration is nearly impossible, and drift remains a persistent challenge at the nanometer scale.

To address this limitation, Nanosurf has developed WaveMode off-resonance imaging for its high-end DriveAFM system. Being up to 15 times faster than similar modes in ambient conditions, WaveMode overcomes the effects of drift through shorter imaging times.

WaveMode is the fastest off-resonance AFM mode available, enabled by the photothermal effect. This effect transfers energy from an infrared laser beam to the cantilever, allowing off-resonance oscillation without the limitations imposed by the f/Q ratio in dynamic mode.

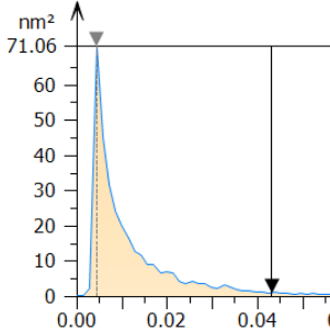

For example, when bottlebrush polymers are deposited onto mica, it becomes possible to count the number of side chains per molecule, a task that is notoriously difficult with conventional AFM techniques. Using WaveMode, our Application team achieved image quality high enough to resolve the entire molecule and accurately count the side chains. This level of detail opens new possibilities for characterizing polymer architecture at the single-molecule level.

Another example involves studying the mechanical properties of polymer particles, which requires AFM-based spectroscopy. The main challenge here is the weak adhesion of polymers to the substrate. Traditional AFM modes often push particles around during measurement, but WaveMode solves this by enabling precise control over the force applied to the sample. This makes it possible to probe mechanical properties without detaching the particles. Fast, gentle, and easy to use, WaveMode is shaping the future of polymer characterization.

10.02.2026

High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

20.01.2026

Read how Nanosurf designs AFM stages to meet industrial challenges, ensuring precision and stability in AFM systems for ...

22.12.2025

Discover how industrial solutions for semicon and precision optics are developed at Nanosurf with insights from Hayato ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

02.07.2024

FridayAFM: learn how to automatize data analysis in MountainsSPIP

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.