High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

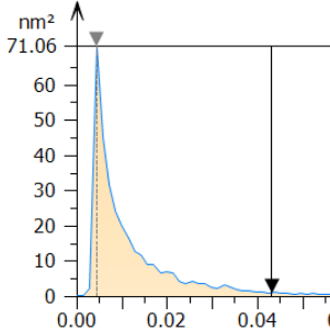

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

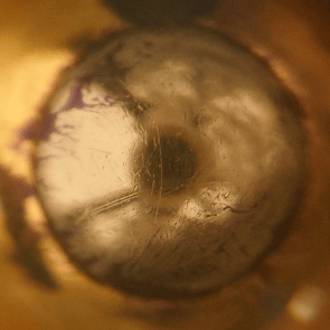

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

AFM for manufacturers: industrial solutions

Sophisticated, multi-component, and high-performance machines like Nanosurf’s industrial solutions require dedicated control logic and software to operate them. These complex atomic force microscopy (AFM) instruments consist of essential components like high precision positioning stages, vibration isolation, acoustic enclosures, and of course the AFM scan head. Crucially, the software that coordinates them is developed by the team led by Felix Gorny, Head of Software Development Industrial Solutions.

Like the mechanical components, the software functionality is based on in-depth discussions with customers and tailored to their needs. “In an industrial setting, good software is based on well-understood requirements and is usually engineered to solve these specific needs. It is therefore not over-engineered and is tested many times to ensure the highest mean time between failures,” Felix says.

Felix Gorny, Head of Software Development Industrial Solutions at Nanosurf.

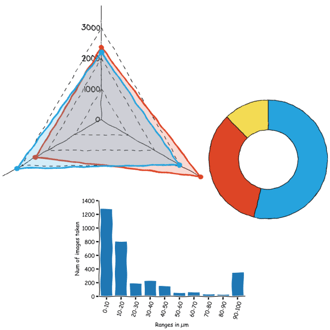

The control logic and software built for the machine interfaces with several different components. For standard products such as Alphacen 300 Drive, it is mainly a matter of configuring parameters for the user’s needs rather than writing new software. For newly designed machines, Felix’s team develops completely or partially new software components, often integrating different code bases and technologies. The AFM controller software for Nanosurf Industrial Solutions is either the new Studio software or Mobile S, its predecessor, depending on the technology used in the machine. There is also software dedicated to the stage and the sample loading mechanism, which is often automated. Additionally, the software must manage data, handle batches of samples, and control cantilever exchange when necessary.

In industrial software and automation projects, work begins long before programming starts. In the requirement phase we define what the system must do and establishes a shared understanding among all parties. These requirements are then translated into a technical concept and documented in a solution design, which guides development and serves as a reference throughout the project.

At the same time, a test protocol is defined together with the customer. Discussing testing early is crucial, especially when customers are involved. “If you speak early about how to test, you can easily spot discrepancies in understanding,” observes Felix. Describing concrete test steps often reveals expectations that were never stated clearly, allowing them to be addressed before implementation begins.

Only after requirements, design, and test protocols are agreed upon does development move forward. Testing is carried out as much as possible in simulation or office environments before deployment. Once the software is installed, the same test protocol is used to verify that everything works as intended. Behind this process are structured tools for version control and project management, which ensure traceability of changes and organize work into manageable steps. Together, these practices help reduce errors, limit rework, and improve overall quality.

Industrial-grade software runs on a programmable logic controller (PLC), a specialized industrial computer designed to automate and monitor processes in manufacturing and production environments. Unlike general-purpose lab AFMs, PLC controlled metrology AFMs are built for reliability under harsh conditions, operating continuously to execute control logic with precision and speed. They read input signals from sensors, process instructions according to a programmed sequence, and send output commands to actuators, ensuring that complex operations run safely and efficiently. Standardized programming languages and robust hardware make PLCs a cornerstone of modern industrial automation.

“These software systems use very specific programming languages and norms, especially for human safety, where the language is simplified as much as possible. During runtime, the software includes latency and cycle time checks to ensure everything is under control,” explains Felix. Mechanical movements are checked before execution in a digital twin of the instrument. The PLC knows the position of each element and verifies that there will be no collisions before sending a movement command.

One of the key aspects that differentiates industrial software from everyday applications used on lab AFM computers is the control of physical movements of objects and tools. When nanometric precision is combined with the high throughput and maximum reproducibility required in industrial environments, the expertise and deep analytical thinking of Felix can make a decisive difference.

10.02.2026

High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

20.01.2026

Read how Nanosurf designs AFM stages to meet industrial challenges, ensuring precision and stability in AFM systems for ...

22.12.2025

Discover how industrial solutions for semicon and precision optics are developed at Nanosurf with insights from Hayato ...

11.07.2024

FridayAFM: learn how to perform datamining on large sets of AFM data.

02.07.2024

FridayAFM: learn how to automatize data analysis in MountainsSPIP

26.06.2024

FridayAFM: learn how AFM makes possible modern ball point pens.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.