High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

AFM for manufacturers: industrial solutions

At Nanosurf headquarters in Liestal, Switzerland, electrical engineers are designing printed circuit boards, while the application team conducts measurements in the laboratories. At the same time, the research team is developing new features for high-end atomic force microscopes, and the sales managers are maintaining close contact with customers. Everyone is diligently carrying out their work. A portion of the workforce is dedicated to a single objective: creating solutions for industry. This is a transversal team that includes engineering, software design, and application specialists, led by Dr. Hayato Omori, Head of Custom Stages.

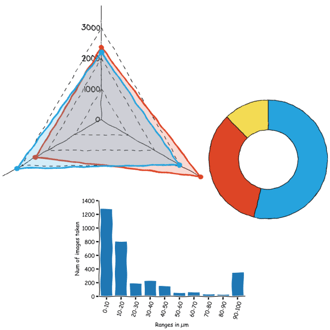

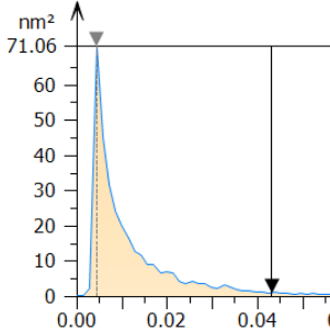

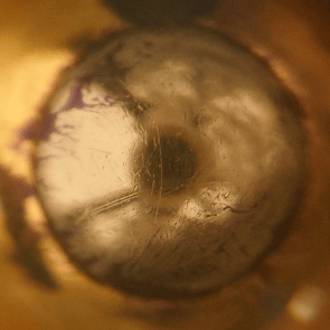

“What I like most about the entire process is coordinating the team and working together to deliver one machine composed of hundreds of different parts and automation,” reflects Hayato. Industrial metrology solutions are typically designed for companies operating in semiconductors or precision optics. In both cases, one of the most common applications is surface roughness measurement. Nanosurf excels in this area thanks to the WaveMode of DriveAFM, the fastest off-resonance technique on the market, and its broad knowledge in building large and robust stage systems WaveMode allows to measure up to 15 times faster than comparable modes in air, ensuring high throughput. The DriveAFM can also be used for challenging measurements, such as sidewalls or wafer edges.

Despite the capabilities of DriveAFM, many additional elements are required to develop a product that provides manufacturers with a fully automated solution. “It all starts with discussions with the customer,” says Hayato. “We gather as many requirements as possible. For this, we use questionnaires that cover the main points. Then we collect information: what they need, what they wish for, what they struggle with, what we can provide, and so on. There is a lot of discussion with the customers.”

Dr. Hayato Omori, Head of custom stages at Nanosurf, in a meeting with his team.

Every customer has a dedicated contact person. Sometimes it is Hayato himself, and in other cases it may be another member of the Nanosurf team specialized in industrial applications. After the requirements are clear and the order is placed, multiple people become involved. Small projects are usually managed by one engineer for design, one person for assembly and one for testing, while larger projects can involve up to five mechanical engineers working alongside five scientists from the development team, as well as five software engineers and two application specialists. The size of the team reflects the care Nanosurf invests in its industrial solutions: high-tech nanoscale engineering combined with robotics and automation.

“The biggest challenge is that you have a single attempt. There is no prototype. You build the system, test it, and then ship it,” says Hayato. Delivering special purpose AFM machinery is complex and involves multiple steps, but customers who need them can leave all the challenges to Nanosurf’s experts. “We are truly an AFM specialists’ company. For the customer, this means they can ask anything from simple questions to the most difficult ones, we have all the expertise to provide answers,” concludes Hayato.

To read more:

DriveAFM Performance without compromise

WaveMode: Simple and Fast Imaging With Accurate Force Control

10.02.2026

High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

20.01.2026

Read how Nanosurf designs AFM stages to meet industrial challenges, ensuring precision and stability in AFM systems for ...

22.12.2025

Discover how industrial solutions for semicon and precision optics are developed at Nanosurf with insights from Hayato ...

11.07.2024

FridayAFM: learn how to perform datamining on large sets of AFM data.

02.07.2024

FridayAFM: learn how to automatize data analysis in MountainsSPIP

26.06.2024

FridayAFM: learn how AFM makes possible modern ball point pens.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.