High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

By Bart Hoogenboom.

Hans Gunstheimera,b, Gotthold Fläschnerc, Jonathan D. Adamsb, Hendrik Hölschera, and Bart W. Hoogenboomb

Link to publication: High-Speed Quantitative Nanomechanical Mapping by Photothermal Off-Resonance Atomic Force Microscopy,

#Done with a DriveAFM: Performance without compromise

One of the great assets of atomic force microscopy (AFM) is its ability to inspect mechanical properties of materials at nanometer resolution. Consequently, AFM has been widely applied for the characterization of materials including metals, polymeric coatings, and living cells and tissues. However, since this requires the AFM probe to move up and down at least once for every pixel in an image, such nanomechanical mapping is time-consuming, taking up to tens of minutes for high-resolution maps.

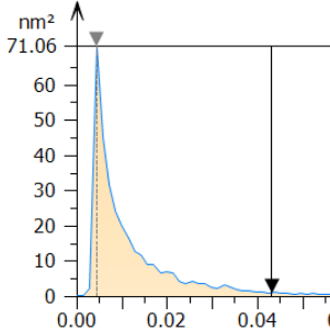

As described in our recent publication, the throughput of such measurements can be enhanced by 1 to 3 orders of magnitude by generating the fast up-and-down movements via an oscillatory laser beam that locally heats the AFM probe. Acting as a bimetal, the probe rapidly moves with the modulated laser intensity, creating the down-and-up movement required to transiently indent the material under study, and hence to determine its mechanical response. This approach was implemented in a DriveAFM with WaveMode NMA (Nanosurf AG, Liestal, Switzerland).

When this approach was first tested, rather unexpected and rich physics emerged, in that the probe motion due to such photothermal actuation strongly depends on the propagation of heat along the probe. Most of these probes are essentially miniature diving boards, called cantilevers; variations in heat propagation along the cantilever translate into different bending shapes and hence different up-and-down movements as a function of time and of position along the cantilever.

To understand this motion and its detection, we established a thermomechanical model of the cantilever response. Next, building on this understanding, we defined a calibration procedure that enabled us to obtain accurate nanomechanical information of sample materials despite the thermomechanical complexities of the probe/cantilever itself.

We tested this method first by measuring the mechanics of a well-defined elastic microfabricated structure (in fact: another cantilever), and next by applying it to more complex materials such as metal alloys and polymer blends. The acquired elasticity data aligned closely and quantitively with expected results, demonstrating the validity of our approach.

In this first study, high-quality data was obtained at up to 25 kHz, which sets the upper limit for the pixel rate at which nanomechanical maps can be acquired. This compares very favorably with the 1~100 Hz pixel rates using traditional nanomechanical mapping, and also with the few kHz pixel rates of other, more recent methods without photothermal actuation.

Ever since the invention of AFM, there has been a push to enhance the throughput of what originally was a rather slow technique. Exploiting the thermomechanical response of AFM probes, we now do nanomechanical mapping at speeds that were previously reserved solely for topographic imaging.

To read more:

WaveMode NMA: High-Speed Nanomechanical Mapping

10.02.2026

High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

20.01.2026

Read how Nanosurf designs AFM stages to meet industrial challenges, ensuring precision and stability in AFM systems for ...

22.12.2025

Discover how industrial solutions for semicon and precision optics are developed at Nanosurf with insights from Hayato ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

02.07.2024

FridayAFM: learn how to automatize data analysis in MountainsSPIP

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.