High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

Transportation, energy production and healthcare. It is difficult to find a field untouched by material science. Metallurgy, in particular, has always accompanied human history and evolution. Bronze was one of the first alloys ever created, so significant that it gave its name to an entire Age. Thousands of years later, steel powered the Industrial Revolution, and today alloys remain fundamental to electronics. Behind every silicon chip lies a hidden network of metal alloys that make modern technology possible. From aluminum-silicon-copper interconnects that keep signals flowing to titanium and tantalum barriers that prevent atomic diffusion, these engineered blends are essential for semiconductor reliability. Even the chips themselves are evolving, with alloy semiconductors such as silicon-germanium and III-V compounds, formed from elements in the third and fifth groups, like gallium arsenide, indium phosphide and aluminum gallium arsenide, driving faster and more efficient devices for the digital age.

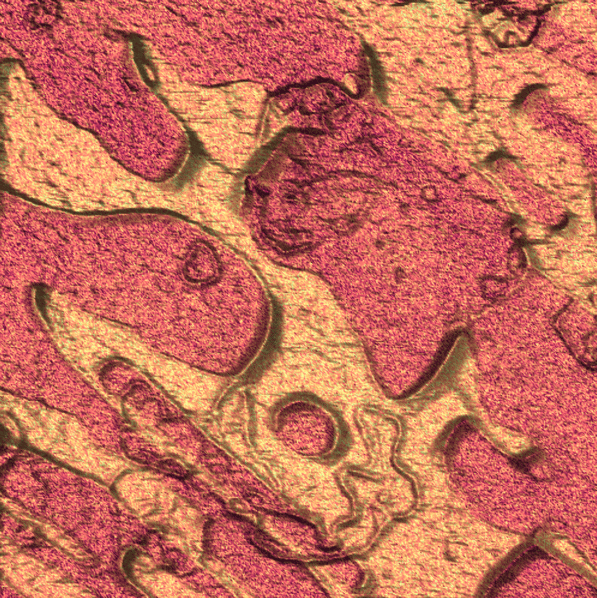

Image of solder tin Sn63Pb37, acquired with DriveAFM on stand-alone material science setup,

resolution: 500 pixel x 500 pixel , scan size: 2 μm x 2 μm.

Today, designing new alloys requires meticulous attention to detail, as they must meet specific requirements for functionality and properties. Mechanical metamaterials, including nano- and micro-architected structures, exhibit characteristics that arise primarily from their geometry rather than their constituent materials. Advances in fabrication techniques have made it possible to create both periodic and disordered architectures, unlocking mechanical behaviors rarely observed in natural materials.

Thanks to tools that allow us to investigate characteristics at the micro- and nanoscale, such as atomic force microscopy (AFM), we can now account for physical properties at these dimensions. The structure of an alloy plays a crucial role in determining its mechanical behavior. Grain and phase boundaries, for example, can restrict the movement of dislocations, influencing plastic deformation. Understanding the arrangement, dominant orientations and scale of phase separation within an alloy is therefore essential for predicting its performance.

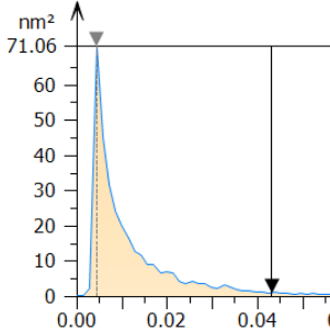

Another common technique for investigating metallic surfaces is nanoindentation, but it is typically quite slow. Nanosurf’s DriveAFM, equipped with CleanDrive photothermal excitation and FastScanning, can scan an area of 1 μm x 1 μm in under 35 s per frame (linerate 15 Hz) at high resolution (512 pixel x 512 pixel) thanks to WaveMode, the fastest off-resonance AFM technique. Moreover, with WaveMode NMA it is possible to directly obtain quantitative elasticity values alongside the usual topography. This makes it straightforward to visualize variations in elasticity, highlighting different phases.

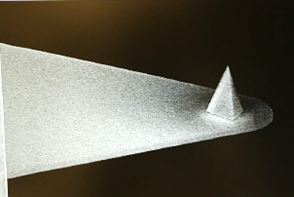

Scanning electron microscope image of a WM20PTD AFM probe used for WaveMode.

With WaveMode NMA, Nanosurf has pushed the boundaries of quantitative measurements on metal alloys, as reported in the peer-reviewed journal SMALL. “The goal of the measurement was to test the upper elasticity range we could access, but indenting metal alloy requires a stiff probe. The stiffer the probe, the more challenging it becomes to drive it through photothermal excitation.” explains Hans Gunstheimer, R&D engineer at Nanosurf and first author of the article. Photothermal excitation in WaveMode is achieved through a second laser focused on the cantilever, which means a stiffer probe requires more laser power to bend. This was made possible through collaboration with an innovative research partner, where a specialized coating for the cantilever was developed. In the study, researchers accurately describe the physics revealed by this method: the motion of the probe under photothermal actuation depends strongly on how heat propagates along its length. Variations in heat distribution across the cantilever lead to different bending patterns, shaping its vertical motion over time and along its span. This understanding is key to fast quantitative nanomechanics without adding complexity. Our Studio software includes everything required for high-resolution, fast, and quantitative measurements, such as all WaveMode NMA controls, quantitative analysis tools, and a one-click calibration workflow. With its intuitive and customizable interface, Studio is easy to use and provides full control over measurements.

10.02.2026

High-end industrial solution are powered by accurate software that coordinate all their functions. Discover the ...

20.01.2026

Read how Nanosurf designs AFM stages to meet industrial challenges, ensuring precision and stability in AFM systems for ...

22.12.2025

Discover how industrial solutions for semicon and precision optics are developed at Nanosurf with insights from Hayato ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

02.07.2024

FridayAFM: learn how to automatize data analysis in MountainsSPIP

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.