Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

Héctor here, your AFM expert at Nanosurf calling out for people to share their Friday afternoon experiments. Today I will show you the engineering of keeping coffee ready to be served.You will learn:

I was going to open this post with some amazing facts about coffee that will thrill and engage everyone, but instead of that I thought: we are in the era of AI, why expending time looking for those amazing facts when they are just a question away? So, here is what ChatGPT thought might catch your attention.

Now that you are fully engaged, I can tell you what I did this week.

I used to drink a lot of instant coffee in pre-made sachets containing coffee, powder milk and sugar, so when during last year one of the major brands changed their sachets, it immediately catch my attention. See the old and new sachets below (big revelation at the end).

Sample 1: Seems paper on the outside, but probably thick plastic in the inside as it doesn't wrinkle.

Sample 3: Outside seems like paper and wrinkles appear relatively easy.

Sample 2: Seems plastic in both inside and outside.

Food packing is a very complex field, because packages, on top of not leaving residues behind, have to protect from air (mostly Oxygen), humidity, and light (mostly UV), and they have to remain stable against chemical reactions for prolonged periods of time.

By the way, one of the most common structures for coffee packaging is PET on the outside (with print layers intercalated with the PET), aluminum in the middle, and low density polyethylene in the inside (see Ref 1).

What I'm trying to say is that food packaging is not changed unless there is a good reason for it. So the intrigue of what is really different between these coffee sachets is huge.

I started by checking if there is aluminum or not.

How?

Using a multimeter of course! But with one key step in the measurement (see at the bottom how this changed the results from a previous fridayAFM). Usually, simply by placing the multimeter pins on aluminum you pierce through the oxide and reach the conductive core, with a layer of LDPE on top... the multimeter electrodes have to be press really hard to reach the metal.

This simple test help me conclude that Sample 2 doesn't have aluminum. So it turns out I was right and some was changed, the other two still have it. As I discovered later, recycling the aluminum from these packages is difficult, so scientists are actively trying to come up with alternative solutions easier to recycle (see Ref 1).

What else could be different?

Next challenge consists in preparing the inner surface for AFM imaging.

Will the coffee powder stick to the surface? If I try cleaning it, will I leave scratches?

Since I have done this in a previous fridayAFM (see at the bottom), I was confident that if I don't touch the inside of the package with my fingers, and immediately pour the powder out after open it, it will not leave a lot of residues. So I put a pair of gloves on, poured the contents of the sachet out, and glued pieces of the sachets on a metallic holder (the cool thing about the holder is that in this way I can move this sample between different AFMs easily). The reason for quickly pouring the coffee out is that humidity in the air will start interacting and likely leaving residue on surfaces.

It is interesting to note here that Sample 2 looks different than the other two, and now we know why (the aluminum is missing), but there could be also something else about the inner coating contributing to this more reflective behaviour.

To my surprise, once under the optical microscope of the AFM, Sample 2 seems to have more residues, so potentially there is something different on its inner coating also.

With the samples ready for AFM imaging the next challenge is to select the right probe and imaging mode.

Since the LDPE layer is very sticky, a low spring constant probe will not be able to overcome the adhesion forces easily and will result in unstable imaging (low lateral resolution), also, any technique involving contact with the sample, is likely to modify the surface of the LDPE, if you don't believe me, just look at the huge adhesion force that arises when using WaveMode.

With these restrictions in place, the obvious choice is to go for a probe with large spring constant that will not bend easily due to the attraction, and to use Dynamic mode for the imaging. In fact, Dynamic mode in the attractive regime to scan as far away from the surface as possible.

The conditions that worked here were a Tap 300 probe, about 20 nm peak to peak oscillation, frequency 10% above the resonance, and a setpoint of 80%.

The results (see above), show that even at the microscale, Sample 2 looks more sticky with far more residue than the other two (in principle the coffee recipe hasn't changed). A part from that, at this scale, and looking only at topography, all samples look more or less the same.

Important note: If you scan a lot over the large particles (likely coffee residue), the probe tends to contaminate and the only way of getting good lateral contrast is to start again with a new probe.

To see details we need to bring the phase contrast. In this case, the phase signal combines adhesion, stiffness and surface-surface attraction to create a contrast, meaning that in principle the signal should have more details than the topography alone. The problem is that if the probe touches the surface, the phase changes dramatically and this results in noise or artefacts in the image. So both setpoint, gains, and scan speed has to be adjusted carefully. For the ranges imaged here, a scan speed of 1 Hz was ideal. The results were these:

Interestingly, all of the samples seem to consists on semi-crystalized polymer (likely LDPE) forming fibers and material in between (this is more obvious on Sample 1 and Sample 2). However, the most interesting part is that the fibers on Sample 2 and Sample 3: have the same size and are similarly arranged. So likely the change between these two is the aluminum and the outside print.

Here comes the big reveal:

Sample 1 Is from a Vanilla Latte, not a cappuccino.

Sample 3 Is the old version of the cappuccino sachet.

Sample 2 Is the new version of the cappuccino sachet,

Let's recap. We got three coffee sachets that seem quite different. Through analysis and imaging we found that and Sample 2 is the newest, without aluminum to easy its recycling, and although visually it seems different than Sample 3 (the old version with aluminum), it shares the same LDPE. Meanwhile Sample 1, which visually seem similar to Sample 3, has quite distinct inner layer, likely specifically designed for the vanilla.

I hope you find this useful, entertaining, and try it yourselves. Please let me know if you use some of this, and as usual, if you have suggestions or requests, don't hesitate to contact me.

Further reading:

[1] Raquel Massulo Souza, Christiane Quartaroli Moreira, Roniérik Pioli Vieira, Leda Coltro, Rosa Maria Vercelino Alves, Alternative flexible plastic packaging for instant coffees, Food Research International, Volume 172, 2023, 113165, ISSN 0963-9969, https://doi.org/10.1016/j.foodres.2023.113165.

[2] Characterization of Polyethylene with DriveAFM

Extra:

On March 2023 fridayAFM was about cappuccino sachets (see below the post from that time). At the time I tried measuring conduction and failed (because I didn't pierce the LDPE layer with the multimeter), and also I came to the conclusion that it was likely a polymer. Now I know it is a semi crystalized polymer with long chains forming fibers and small chains in between to join them together.

Cool.

Will this journey continue?

We will see.

28.10.2025

Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

27.10.2025

Read this blog and discover advanced alloy engineering and cutting-edge AFM techniques for high-resolution, ...

14.10.2025

Discover how WaveMode technology resolves the tobacco mosaic virus structure under physiological conditions with ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

11.07.2024

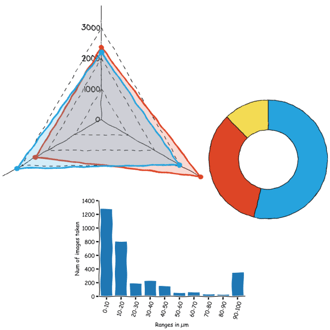

FridayAFM: learn how to perform datamining on large sets of AFM data.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.