Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

Héctor here, your AFM expert at Nanosurf calling out for people to share their Friday afternoon experiments. Today I bring you some candy.

Food, and specially sweets have been a recurring theme on fridayAFM. This is because sugar can crystalize forming crystals, and the crystallization conditions, the type of sugar, and the impurities (considering any extra ingredient as impurity), can greatly affect the final product.

For instance, on a previous fridayAFM, we investigated sugar glass which is formed by dissolving the sugar in water and then letting the water dry slowly.

Thanks to the slow formation, the sugar molecules can arrange themselves into a crystal lattice and because the lattice is not parallel to the surface, we get to see the terraces. In other cases were the crystallization is faster, the sugar tends to form small crystals randomly oriented, an example of this is the pearl sugar.

In general, the state diagram for sugar is well understood, and used to create all shorts of foods. However, there is a process that messes up with that diagram. Between fast and slow crystallization there is a process called sugar panning (a.k.a. drageeing), where not only the humidity and temperature change over time, but also a mechanical action is added. Panning is performed inside of a tumbler and can be used to generate beads of specific size or to coat with sugar other elements (e.g. the chocolate nucleus of the M&M candy). The next video shows how panning is used to create silver pearls.

and in the video below, how panning can be used to candy-coat chocolate.

Interestingly, in another fridayAFM we investigated already the M&M candy. We showed that in this case the coating resembles more of gravel than of crystal, with small nanoparticles in it.

To show you how the panning can give rise to very different structures, I bring you today a few other candies that (probably) were produced through panning.

Two of the candies (M&M and Skittles) look very similar, the Pinballs look a little bit more shiny, and the sugar pearls are very reflective. In principle, all these have a sugar coating, and it is likely that all of them were fabricated using the panning technique.

The first one, the sugar pearl shows a surface that has quite a lot of patches quite flat, formed of grains aggregate. It almost looks like the surface was hit many times until the grans compacted onto solid masses. It is likely that these flat surfaces is what it gives this candy its high reflectivity.

The second one shows very little reflection, and this is corroborated by a quite rough surface. Given that the inside material breaks a part quite easily on this one, probable the tumbling process was quite mild, either at low speed or for a short period of time.

The results with the M&M match what we saw in a previous fridayAFM, a quite uniform distribution of spherical grains. Probably the effect of tumbling for a long time.

The last one, the Skittles, resemble quite a lot the M&M, in terms of flatness and homogeneity on the grain size and coverage. Again, probably quite a thorough tumbling.

So... the mechanical stress generates a large variety of finishes (assuming the rest of the process was similar for all the different types of candy), allowing to go from rough surfaces to shiny reflective ones. Which one is more appealing to the eyes and to the tongue? Up to you!

Of course, a more thorough experiment will involve a panning machine and many rounds of fabrication and testing... but until I upgrade my kitchen, this is the best I can offer. I hope you enjoyed what I showed you. Stay in touch, and if you have more info, please share.

28.10.2025

Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

27.10.2025

Read this blog and discover advanced alloy engineering and cutting-edge AFM techniques for high-resolution, ...

14.10.2025

Discover how WaveMode technology resolves the tobacco mosaic virus structure under physiological conditions with ...

08.12.2024

Learn how to make a Python code to interface your AFM with a gamepad.

01.10.2024

Discover how different types of glass age and degrade over time, and learn how to use AFM technology to investigate ...

11.07.2024

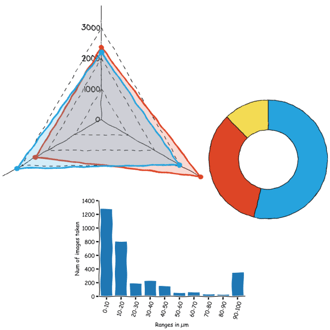

FridayAFM: learn how to perform datamining on large sets of AFM data.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.